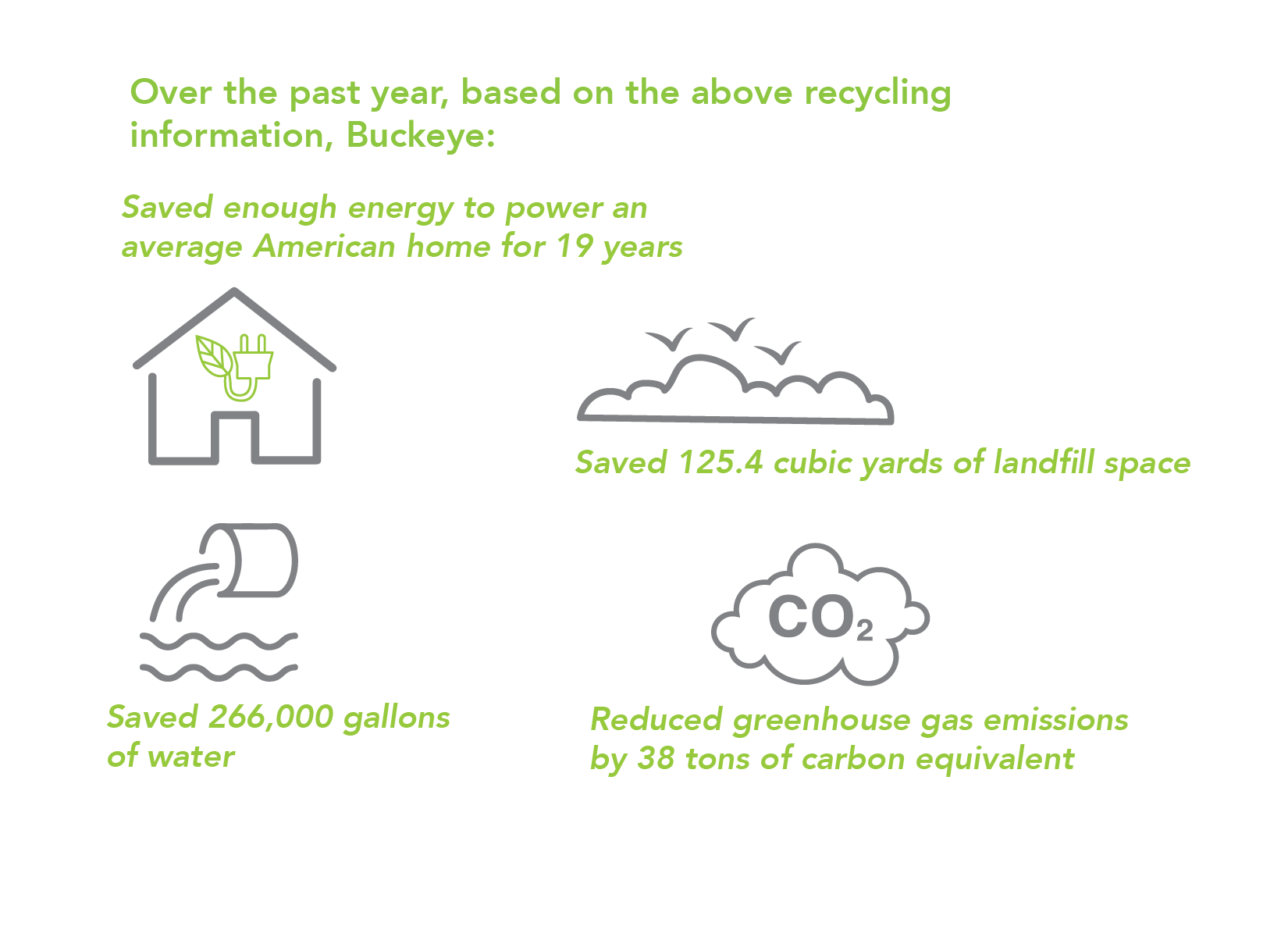

Every year on April 22, Buckeye takes a moment to recognize our planet and the importance of protecting it. Sustainability is at the core of what we do, and one key area where we can make a significant impact is reducing plastic waste—especially when it comes to trash liners.

Reducing Plastic with Gateway® Liners

At Buckeye, innovation and sustainability go hand in hand. That’s why we’ve designed Gateway® liners to reduce plastic waste without sacrificing performance. Compared to traditional liners, Gateway® liners use 19% less plastic, contributing to a more sustainable future.

Even with less plastic, Gateway® liners remain stronger than other leading liners due to the high-quality resins used in their production. These resins enhance durability, ensuring the liners maintain their strength and reliability.

Why is this important? In the trash liner industry, the best way to minimize environmental impact is through source reduction or reducing the total plastic that ends up in landfills.

Hard Plastic Recycling (Containers & Packaging)

More than 75% goes to a landfill

Less than 25% is recycled

Plastic Trash Liner Recycling

More than 99% goes to a landfill

Less than 1% is recycled

Since most plastic liners end up in landfills—where they can take up to 500 years to decompose—Gateway® focuses on reducing plastic from the start.

R-Spec® 2.0

Gateway has continued to improve sustainability initiatives with their newest product formulations. Gateway’s latest development, R-Spec® 2.0, utilizes new resin technology. These liners are now 15-20% stronger while using even less plastic.

Sustainability Without Compromise

Our commitment to sustainability drives us to develop innovative, high-performance, and cost-effective products, packaging, and programs that prioritize health and safety. Every product in our programs is designed with human health and environmental responsibility in mind.

One of the themes this year for Earth Day is to educate others and to commemorate Earth Day, we offer educational tools in our programs that educate users along with providing training programs that emphasize worker and environmental safety. Our training programs also provides standardized procedures to help reduce product usage, labor, and overall costs.

Buckeye remains dedicated to creating reliable, sustainable solutions that minimize environmental impact and enhance the well-being of those who use them. To learn more about our sustainability initiatives and products, contact your local sales representative.

In our sustainability efforts, we have always prioritized safety for workers and the environment. We are committed to enhancing product performance and safety through specialized training programs and education. In continuation of this, Buckeye has also field tested and approved changes to the following products that do not contain intentionally added PFAS:

In our sustainability efforts, we have always prioritized safety for workers and the environment. We are committed to enhancing product performance and safety through specialized training programs and education. In continuation of this, Buckeye has also field tested and approved changes to the following products that do not contain intentionally added PFAS:

Liquescent Technology

Liquescent Technology

Eco

Eco